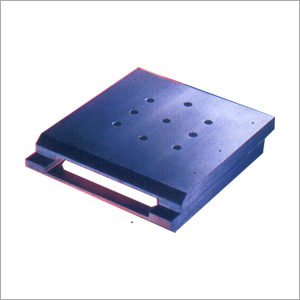

Strip Graphite Casting

Strip Graphite Casting Specification

- Material

- Graphite

- Application

- Continuous casting, metallurgy, jewelry casting, glass industry, and laboratory applications

- Chemical Composition

- High Purity Graphite (generally Carbon content > 99%)

- Shape

- Strip

- Hardness

- 50-60 HSD

- Density

- 1.85 Gram per cubic centimeter(g/cm3)

- Oxidation Resistance

- Good in non-oxidizing atmosphere

- Thermal Conductivity

- High (approx. 120-150 W/m·K)

- Surface Finish

- Smooth, precision machined

- Electrical Conductivity

- Excellent

- Size Range

- Customizable as per requirements

- Compressive Strength

- 80 MPa

- Maximum Service Temperature

- Up to 3500°C (in inert atmosphere)

- Color

- Greyish Black

- Porosity

- Low

About Strip Graphite Casting

Owing to our robust infrastructure facility, we have emerged as a conspicuous manufacturer, supplier and exporter of Strip Graphite Casting. By employing latest technology, we manufacture these castings in adherence with the set industry standards. Extensively used in industrial applications, these castings are available in different sizes and technical specifications. At our packaging unit, we make use of high-grade packaging material to pack this Strip Graphite Casting in an efficient manner.

Features:

- Enhanced efficiency

- Corrosion resistance

- Durable

- Resistant to heat

Exceptional Performance in Extreme Conditions

Designed for demanding environments, these graphite strips deliver superior thermal conductivity and impressive mechanical strength. Their capacity to withstand temperatures up to 3500C in inert atmospheres makes them suitable for high-temperature industrial processes, while their excellent electrical properties ensure versatility in various technical applications.

Precision Crafted for Reliability

Every strip is precision machined to provide a smooth surface finish and low porosity, resulting in reliable performance and ease of integration into your projects. High-purity graphite enhances durability and consistency, making these strips a dependable choice for critical casting and laboratory processes.

Customizable Solutions for Diverse Industries

As an exporter, supplier, and manufacturer, we offer customizable size options to meet unique industry specifications. From metallurgy to jewelry casting, these strips provide adaptable solutions for professionals demanding high-quality materials and consistent results.

FAQs of Strip Graphite Casting:

Q: How are strip graphite castings used in continuous casting and metallurgy?

A: Strip graphite castings are widely used as molds and liners in continuous casting and metallurgy due to their high thermal conductivity and resistance to high temperatures. They help in shaping and cooling molten metals efficiently, ensuring smooth and consistent outputs.Q: What is the process for customizing the size of graphite strips?

A: We provide customizable sizing based on your specific requirements. After discussing your needs, our technical team precision-machines the strips from high-purity graphite blocks to ensure the desired dimensions, high surface quality, and low porosity.Q: When is it best to use these graphite strips in laboratory applications?

A: These graphite strips are ideal for laboratory applications requiring high thermal and electrical conductivity, such as furnace components, electrodes, or heat shields, especially when operating in inert atmospheres or at extremely high temperatures.Q: Where are graphite strip castings commonly applied besides metallurgy?

A: Apart from metallurgy, graphite strip castings find use in jewelry casting, the glass manufacturing industry, and various laboratory experiments that demand materials with high purity, stability, and excellent resistance to thermal stress.Q: What benefits does high purity (>99% carbon) graphite provide in these strips?

A: High-purity graphite offers improved performance in terms of conductivity, structural integrity, and chemical stability. It reduces the risk of contamination during sensitive processes, ensuring reliable results in industrial and laboratory settings.Q: How does the smooth, precision-machined finish enhance usage?

A: The smooth, precision-machined finish provides excellent surface quality, minimizing adhesion of molten metals or glass and facilitating easy removal of finished products. It also enhances fit and integration into automated production lines.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Graphite Crucibles Category

Graphite mould

Price 500 INR / Unit

Minimum Order Quantity : 100 Units

Material : Stainless Steel

Shape : Rectangular

Application : Industrial

Graphite Elements

Minimum Order Quantity : 1000 Units

Material : Graphite

Shape : Rod, Tube, Plate, Custom Shapes

Chemical Composition : High Purity Carbon/Graphite (usually >99%)

Vertical Graphite Casting Die

Material : High Purity Graphite

Shape : Custom Cylindrical or Rectangular as per Design

Chemical Composition : Carbon 99.9%

Application : Vertical Graphite Casting Die for Metal Casting, Precious Metal Molds, and Continuous Casting Processes

Industrial Graphite Crucibles

Material : High Purity Industrial Graphite

Shape : Cylindrical / Conical Open Top

Chemical Composition : Carbon Content > 99%, Trace Impurities

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS