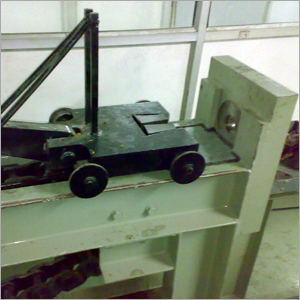

Draw Bar Bench Machinery

Draw Bar Bench Machinery Specification

- Operating Temperature

- 5C to 45C

- Control System

- PLC Control Panel

- Frequency

- 50/60 Hz

- Drive

- Gear & Chain Driven

- Noise Level

- Low (< 80 dB)

- Model No

- Available in Multiple Models

- Machine Type

- Bar Drawing Bench

- Frame Type

- Heavy Duty Welded Steel

- Lubricating System

- Centralized Automatic

- Accuracy

- 0.1 mm

- Cooling System

- Forced Water Cooling

- Power Rating

- Standard 3 Phase

- Product Type

- Draw Bar Bench Machinery

- Technology

- Hydraulic and Mechanical

- Power Source

- Electric

- Pressure

- Up to 300 Tons

- Dimension (L*W*H)

- Varies as per model (e.g., 7000x1800x1600 mm)

- Color

- Blue & Yellow (Standard)

- Production Capacity

- Customized as per requirement

- Usage & Applications

- Tube and pipe drawing, metal shaping, bar straightening

Draw Bar Bench Machinery Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cheque, Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- Unit

- Packaging Details

- Wooden Box Packaging.

- Main Export Market(s)

- Western Europe, Africa, Central America, Australia, Middle East, South America, Asia, Eastern Europe, North America

About Draw Bar Bench Machinery

Being a client focused organization, we have been recognized as an eminent manufacturer, supplier and exporter of Draw Bar Bench Machinery. Manufactured using latest technologies, this machinery is highly appreciated in different industrial segments. The machinery we offer is rigorously checked by our quality analyzers on well defined parameters to ensure its precision. To ensure utmost client satisfaction, this Draw Bar Bench Machinery is available in various sizes and technical specifications.

Features:

- Longer service life

- Abrasion resistance

- High tensile strength

Other details:

We are offering Draw Bar Bench Machinery. In these machine we uses high response proportional variable pump,injection and mold lock for differential control. With strong drive system, advantaged technical parameters, and whole machine performance, it has greatly enhanced its performance to price ratio.

Versatile Applications for Metal Shaping Industries

Designed to meet demanding requirements, Draw Bar Bench Machinery is ideal for tube and pipe drawing, metal shaping, and bar straightening processes. Its adaptability across various industrial sectors enables enhanced production flexibility, making it suitable for both large-scale manufacturers and specialized metalworking facilities.

Advanced Control and Efficient Performance

Equipped with a modern PLC Control Panel, the machinery guarantees precise operation and easy customization for different tasks. The combination of hydraulic and mechanical technologies, alongside centralized automatic lubrication and forced water cooling, ensures optimal performance, reduced downtime, and a prolonged operational lifespan.

Customizable Production and User-focused Design

With production capacity tailored to project requirements and options in multiple models, users benefit from a scalable solution. The heavy-duty, welded steel frame provides exceptional stability, while the low-noise and accurate operation (0.1 mm) enhance operator comfort and process reliability.

FAQs of Draw Bar Bench Machinery:

Q: How does the Draw Bar Bench Machinery enhance metal shaping and drawing processes?

A: The machinery provides up to 300 tons of pressure through a precise hydraulic and mechanical system, ensuring consistent results in tube and pipe drawing, metal shaping, and bar straightening. Its 0.1 mm accuracy and PLC-controlled operations streamline workflow, improve quality, and enable efficient large or small-scale production.Q: What types of materials or products can be processed using this machinery?

A: Draw Bar Bench Machinery is engineered for processing tubes, pipes, and metal bars, making it suitable for applications in automotive, construction, and general metalworking industries where shaping, drawing, and straightening are required.Q: When is forced water cooling necessary for operation?

A: Forced water cooling is essential during prolonged or high-capacity processes to maintain optimal operating temperatures and prevent overheating. This feature ensures consistent performance, even during intensive, continuous production runs.Q: Where can the Draw Bar Bench Machinery be installed?

A: This machinery can be installed in various industrial environments such as manufacturing plants, metal fabrication workshops, and large-scale production facilities. Its robust construction and customizable dimensions allow integration into both existing and new industrial setups.Q: What is the process for customizing production capacity or dimensions?

A: Customers can specify their production needs and preferred machine dimensions when placing an order. The manufacturer then configures machinery specifications accordingly, offering tailored solutions to support specific industrial requirements.Q: How does the centralized automatic lubricating system benefit maintenance routines?

A: The centralized automatic lubricating system ensures consistent and optimal lubrication to all necessary moving parts. This reduces wear, lowers maintenance demands, minimizes downtime, and contributes to the longevity and reliability of the machine.Q: What are the main benefits of the heavy-duty welded steel frame?

A: A heavy-duty welded steel frame provides outstanding structural integrity and stability, reducing machine vibrations during operation. This not only enhances machining precision but also ensures operational safety and the longevity of the equipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Drawing Machinery Category

Industrial Drawing Machinery

Minimum Order Quantity : 1 Unit

Weight (kg) : 2500 kg

Lubricating System : Automatic

Product Type : Other, Industrial Drawing Machinery

Surface Treatment : Other, Powder Coated

Connectivity Options : Ethernet, USB Interface

Drawing Machineries

Minimum Order Quantity : 1 Unit

Weight (kg) : 2300

Lubricating System : Automatic Lubrication

Product Type : Other, Drawing Machineries

Surface Treatment : Paint Coated, Other

Connectivity Options : Basic Digital Panel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS